Opti Panels

Product Description

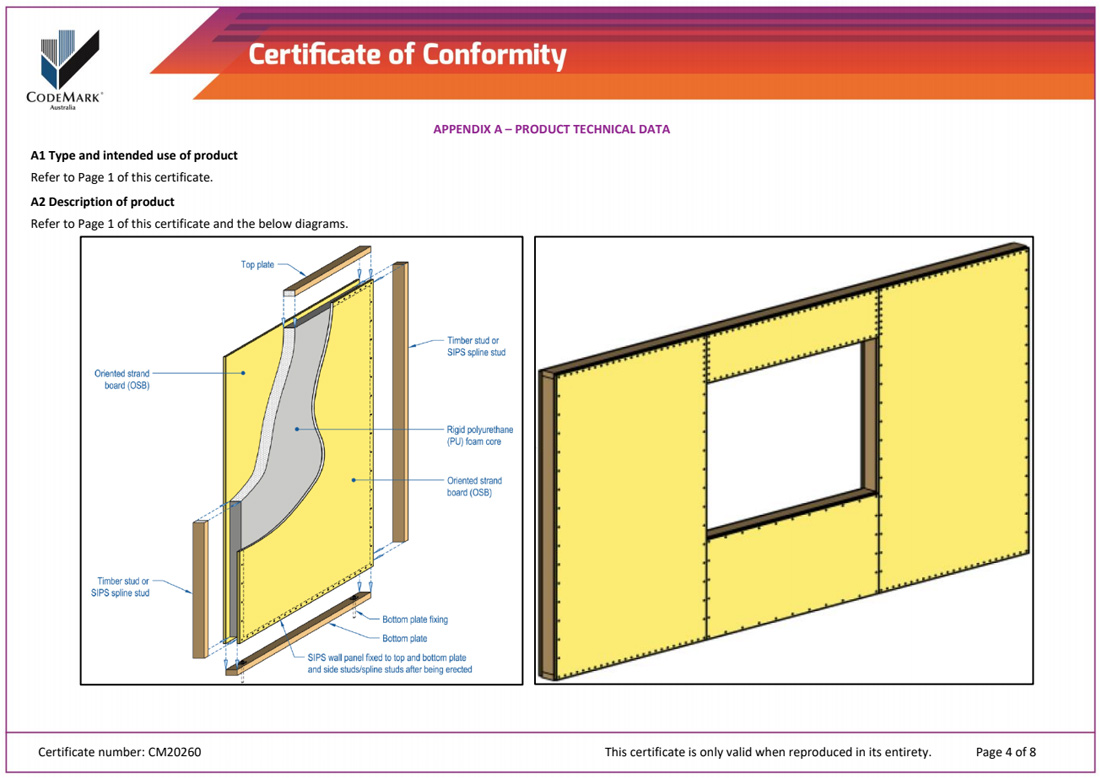

The Modex OptiPanel Panel is a load bearing structural insulated panel system (SIPs) element capable of resisting vertical gravity actions, out-of-plane loads and in-plane racking loads. The SIPs panel consists of a rigid polyurethane (PU) foam core that is bonded between an oriented strand board (OSB) panels on either face of the panel to allow the outer two faces to act as one composite wall section

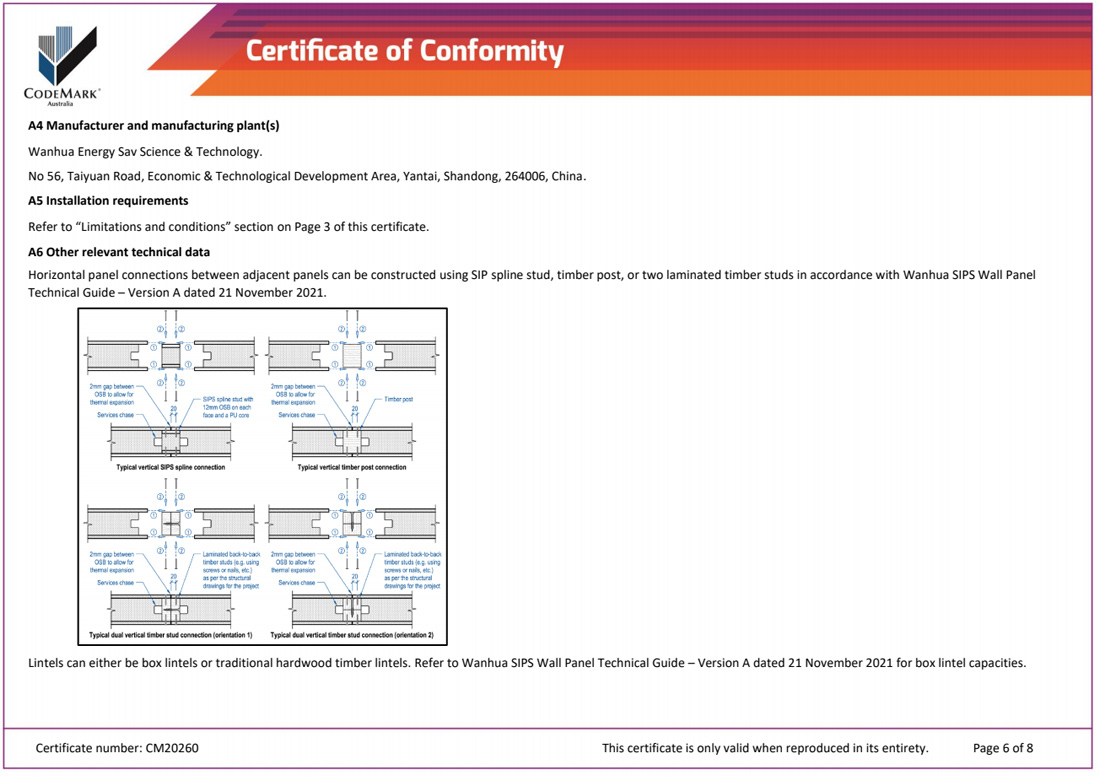

② Oriented strand board(OSB)

③ Timber stud or SIPs spline stud

④ Rigid polyurethane (PU) foam core

⑤ Bottom plate fixing

⑥ Bottom plate

⑦ SIPs wall panel fixed to top and bottom plate and side studs/spline studs after being erected

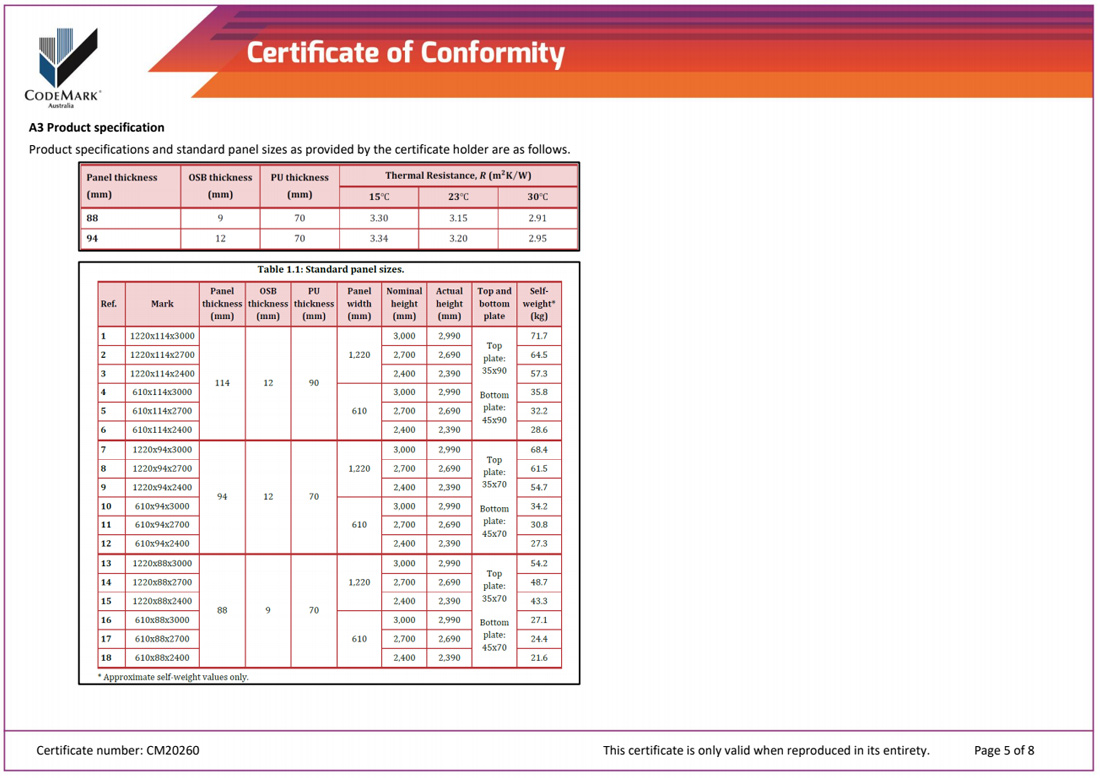

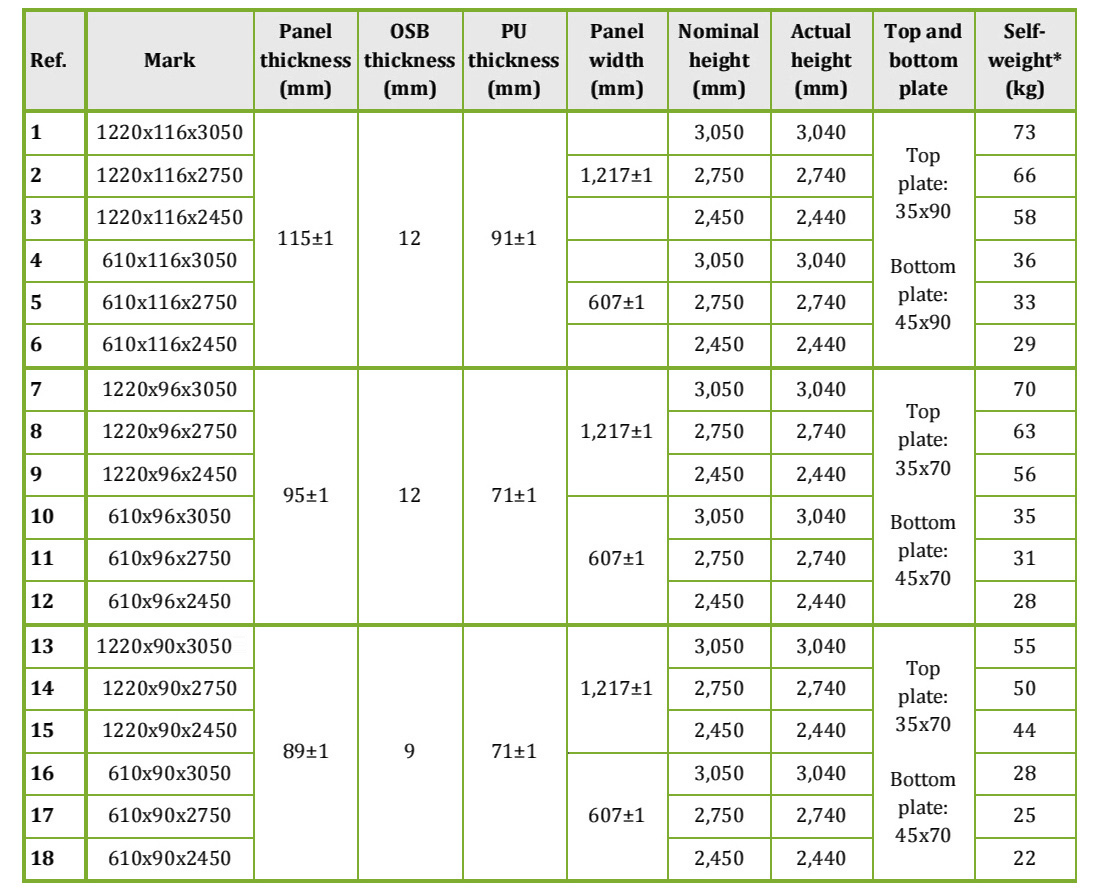

Standard Panel Sizes

* Approximate self-weight values only.

Polyurethane

Modex Optipanels uses a dense polyurethane core to provide high thermal insulation, sound and impact resistance and which is load bearing, like a timber frame. Polyurethane is a dense foam material made from polyurethane. Polyurethane is superior to other insulated materials such as polyethylene and polystyrene and provides better insulation, impact and sound resistance.

Modex Optipanels Wall Panels have two products to choose from depending on the design and scope of the project, Rigid Polyurethane (PUR) and Rigid Polyisocyanurate (PIR) Panel. Due to its chemical formulation PIR is denser and provides significantly better Fire Resistance properties than standard Flame-Retarded Polyurethane Foam Systems and can also be used in a wider exposure temperature range than Polyurethane Foam Systems.

The elimination of thermal bridging and a more airtight envelope contributes to the higher whole wall R-value of structural insulated wall panels, compared to the conventional metal and wood stud walls or SIPs panels made from polystyrene.

Installation Process

Modex Optipanels is an innovative new technology that provides our customers with a product which is simple, inexpensive and quick to install. Our panels replicate the advantages of timber frames. They are load bearing, stronger, have a polyurethane insulation, built-in electrical conduits for easy installation of power, thermal and sound ratings.

Production Process video >

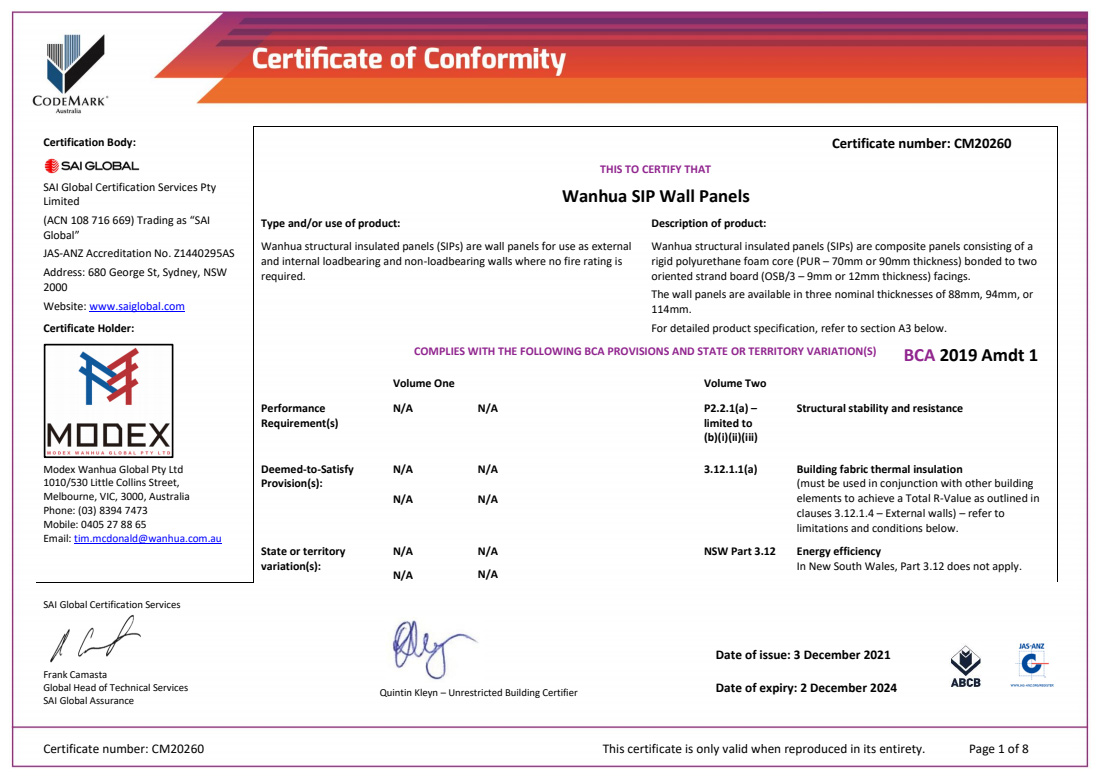

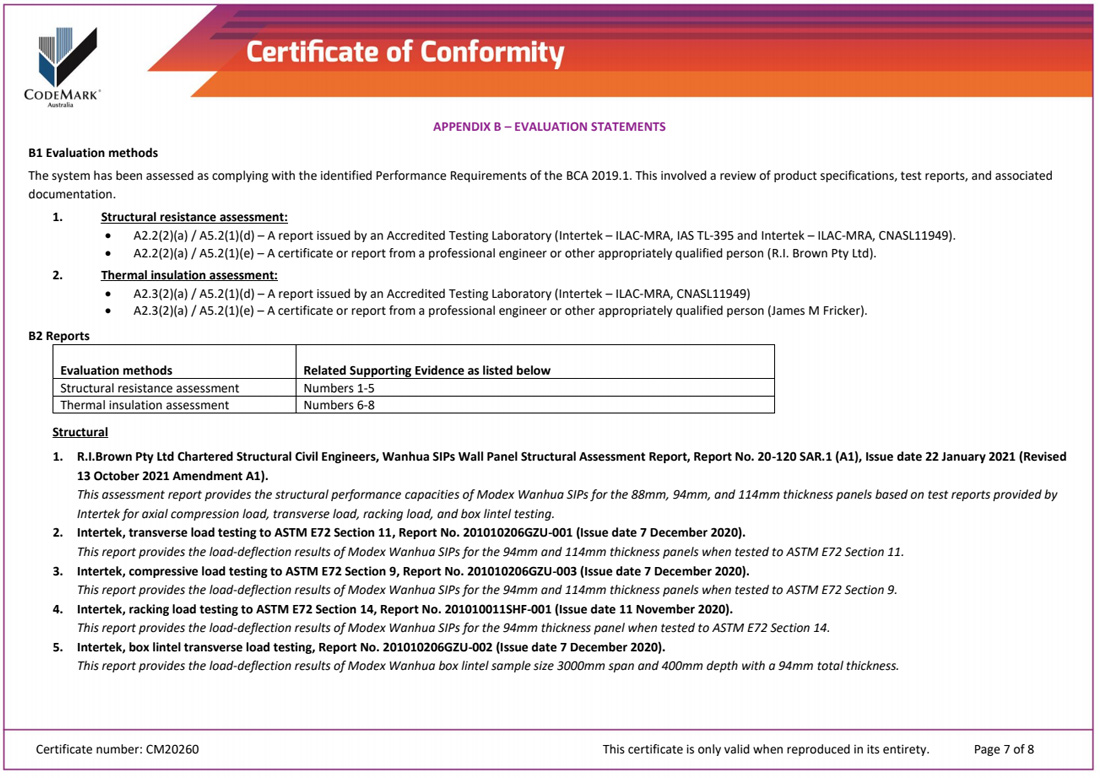

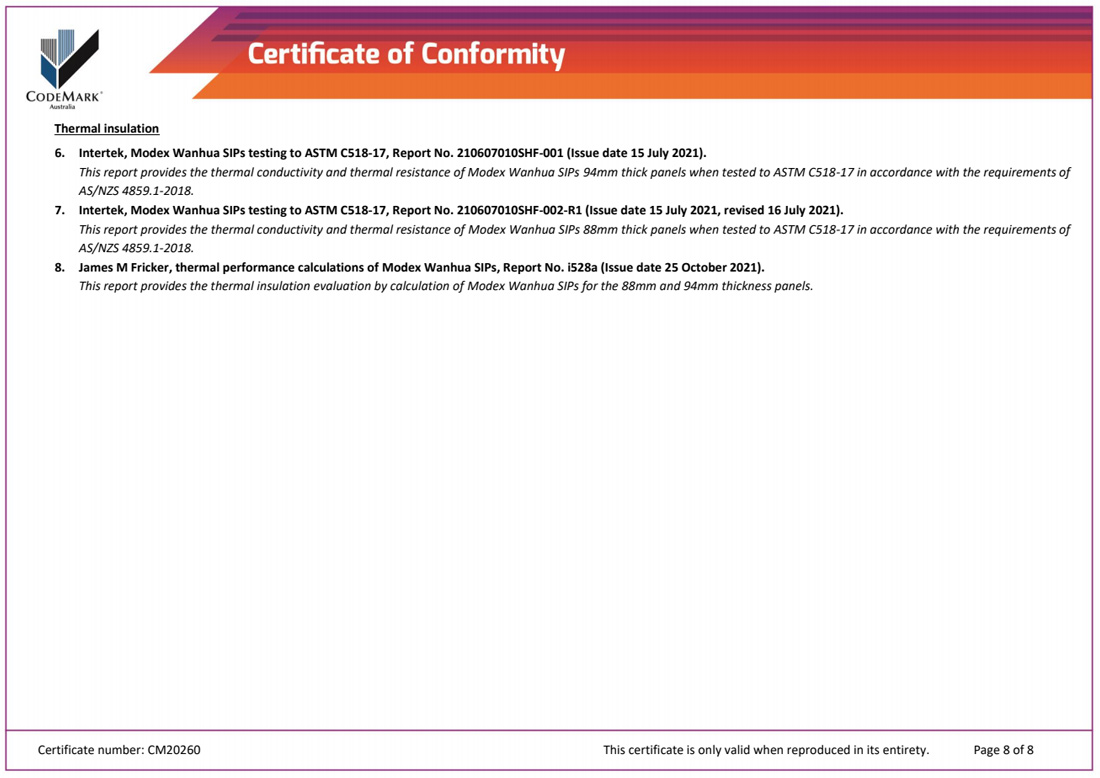

Certification

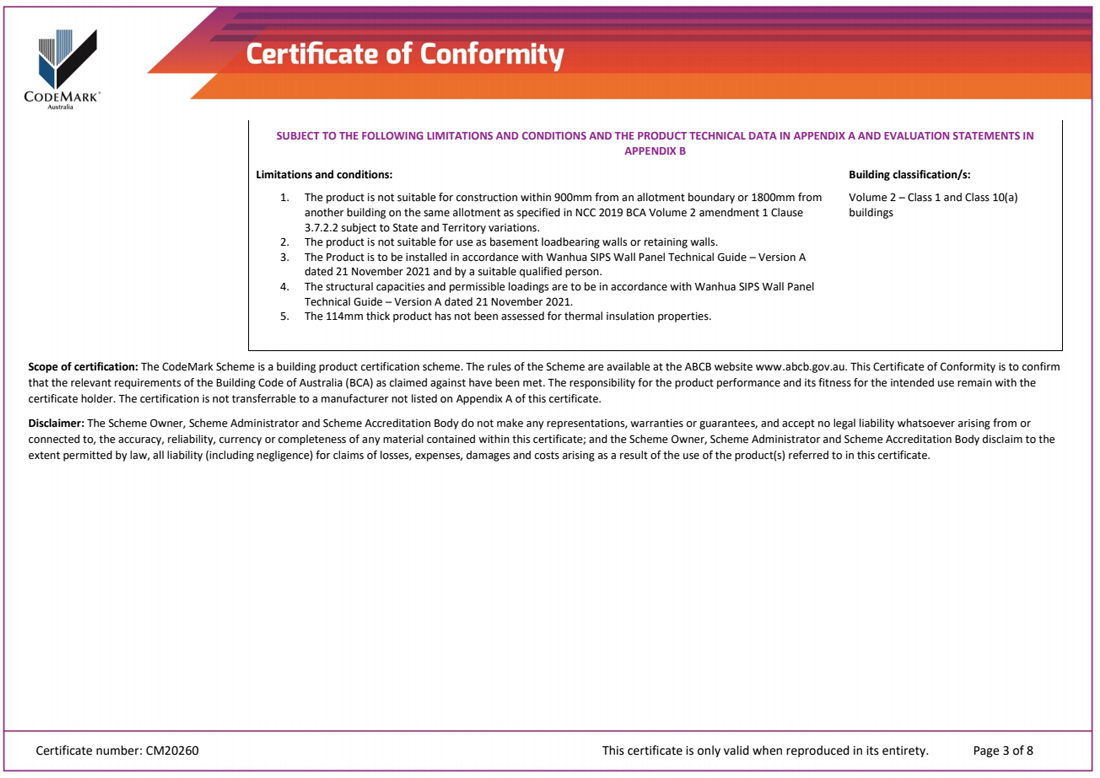

Modex Optipanels are Codemark Certified to comply with the Australian National Construction Code. Our panels and their manufacture have stood up to the most rigorous testing and compliance standards.

Our wall panels have been designed with our expert team of engineers and designers and has received Codemark certification. Any project can be confident that it is working with a product that is stronger than the traditional timber frame and comes with Codemark certification. Unlike timber frames, our Codemark certified wall panels and the factories where they are manufactured are regularly audited to ensure safety and product integrity at the highest level.

Application Scenario

Class 1 buildings are houses. TypicalIy they are standalone single dwellings of a domestic or residentiaI nature. They can also be horizontally attached to other Class 1 buildings such as terrace houses, row houses, or townhouses. In these situations they must be separated by a wall that has fire—resisting and sound insulation properties.

A Class 1a building is a single dwelling being a detached house; or one of a group of attached dwellings being a town house, row house or the like.

A Class 1b building is a boarding house, guest house or hostel that has a floor area less than 300 m2, and ordinarily has less than 1 2 people living in it. It can also be four or more single dwellings located on one allotment which are used for short-term holiday accommodation.

OR STRUCTURES

OR STRUCTURES

Class 10 buildings are non-habitable buildings or structures. Class 10a buildings are non-habitable buildings including sheds, carports, and private garages.

Energy efficiency

Modex Optipanels will help your home reach high energy star ratings at a low cost. The combination of OSB (Oriented Strand Board) and the polyurethane core provides a wall panel which has properties for high thermal insulation.

-

90% Recyclable materials and environmentally friendly

-

Thinner wall design and being post free saving 8.5% in space

-

Optipanel’s insulation has up to a 50% high R value than timber framed walls and

-

Gaps or spaces made in the wall panels can be filled in to ensure the insulation integrity of the walls

-

The construction period of the walls is up to 60% less than that of traditional timber frames

-

Polyurethane is water resistant

Comparison Data Sheet

FOAM SALES' RIGID BOARD INSULATION MATERIALS

R' VALUE (THERMAL RESISTANCE) AT SPECIFIED THICKNESSES (MM)

| Thickness (mm) | Expanded Polystyrene (EPS) SL Grade 13kg/m3 |

Expanded Poystyrene (EPS) VH Grade 28kg/m3 |

Saviro XPS Blue Board 32kg/m3 |

Rigid Polyurethane (PUR) 35kg |

Polyisocyanurate (PIR) 40kg/m3 |

Saviro Phenolic Foam 45kg/m3 |

| 10 mm | 0.25 | 0.29 | 0.36 | 0.43 | 0.46 | 0.40 |

| 15 mm | 0.37 | 0.44 | 0.54 | 0.65 | 0.69 | 0.59 |

| 20 mm | 0.50 | 0.59 | 0.71 | 0.87 | 0.93 | 0.79 |

| 25 mm | 0.62 | 0.74 | 0.89 | 1.08 | 1. 16 | 1.00 |

| 30 mm | 0.75 | 0.88 | 1.07 | 1.30 | 1.38 | 1. 18 |

| 40 mm | 1.00 | 1. 18 | 1.43 | 1.74 | 1.86 | 1.58 |

| 50 mm | 1.25 | 1.47 | 1.79 | 2. 17 | 2.32 | 1.97 |

| 75 mm | 1.87 | 2.21 | 2.68 | 3.26 | 3.49 | 2.96 |

| 100 mm | 2.50 | 2.94 | 3.57 | 4.35 | 4.64 | 3.95 |

| 150 mm | 3.75 | 4.41 | 5.36 | 6.52 | 6.97 | 5.93 |

| 200 mm | 5.00 | 5.84 | 7. 14 | 8.69 | 9.30 | 7.91 |

| 250 mm | 6.25 | 7.35 | 8.93 | 10.87 | 11.60 | 9.88 |

| 300 mm | 7.50 | 8.82 | 10.71 | 13.04 | 13.92 | 11.86 |

| (W/m.K) at 23C. 0.040 | (W/m.K) at 23C. 0.034 | (W/m.K) 0.028 | (W/m.K) 0.023 | (W/m.K) 0.0215 | (W/m.K) 0.0253 | |

| R' Value (Thermal Resistance) = Thickness in meters / Thermal Conductivity | ||||||